November 5, 2020

How do we determine the correct fan and how do we ensure that it provides sufficient cooling, with lowest power consumption, least noise and vibration, and longest lifetime?

What method gives the best results and are there even better ways? In TOP TECH TALK we illustrate this with examples and also explain the choices.

|

|

|

Of course, the shape of a fan is an important choice option. It has quite an impact on the size and appearance of a device. Every application has its own possibilities and limitations. For many applications an ordinary axial fan is sufficient, for others a blower or centrifugal fan is the best choice. In addition, a fan is not always used for cooling, but also to remove, for example, toxic gases or bad smells. In this article we limit ourselves to the axial fan which is used for cooling electronic equipment.

When determining the right fan, there are a number of important factors to consider and, giving several challenges:

All the above factors are interrelated and influence each other. This does not make it any easier to choose a fan. In general, we see that 3 methods are used to determine the type and version of the fan.

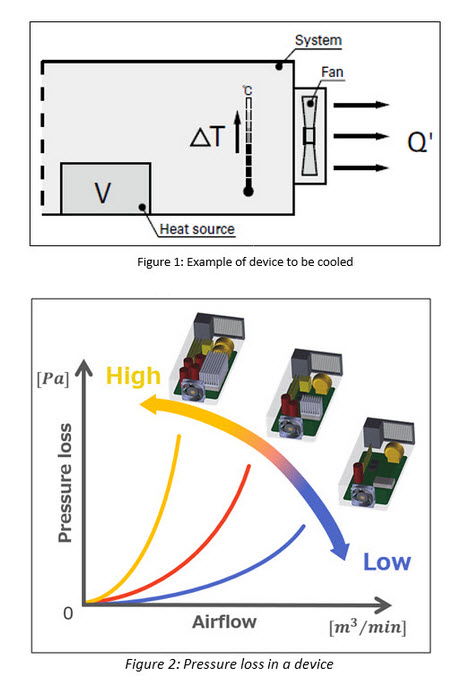

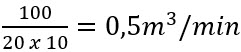

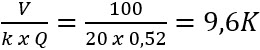

Here K is a constant for the specific gravity of the air multiplied by a specific heat and is set at 20.

Here K is a constant for the specific gravity of the air multiplied by a specific heat and is set at 20.For example, if a device dissipates 100W and causes a temperature rise of 10K, this will require an airflow of

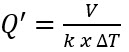

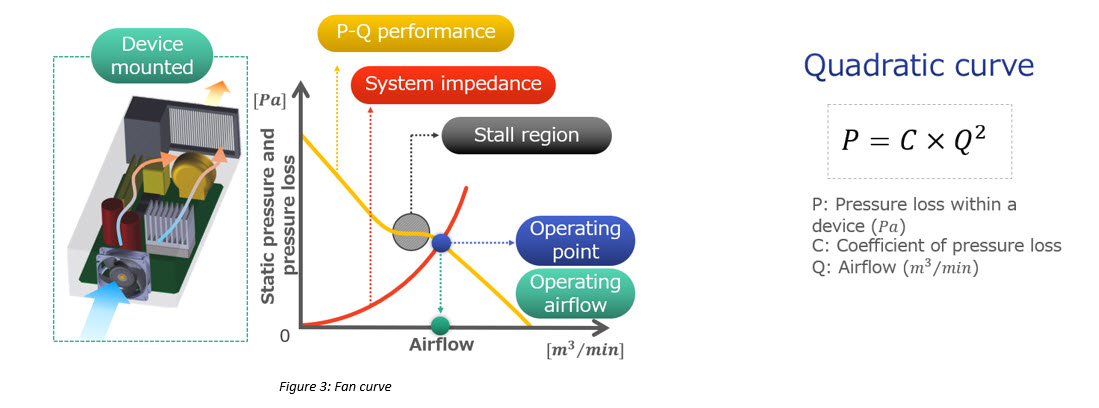

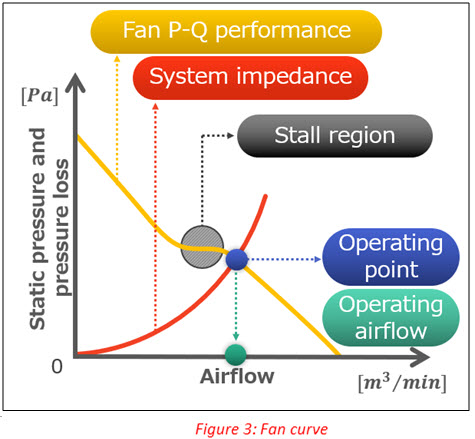

In the curve of a fan (see figure 3) we can see that the air flow, air pressure and static pressure are closely related. As we have read, the static pressure is mainly determined by the system impedance of an application. But that's just it; we usually do not know this system impedance and it is difficult to measure.

.

.

The temperature rise ∆T is then limited to  . With this we have made a rough estimate, but because we still do not know how this relates to the static air pressure, it will have to be shown in practice whether the selected fan is sufficient.

. With this we have made a rough estimate, but because we still do not know how this relates to the static air pressure, it will have to be shown in practice whether the selected fan is sufficient.

We are not there yet with determining the fan based on the required air flow. As mentioned earlier, you also want to limit the power consumption (electrical power) and noise level in a device. The values for power and noise level stated in a data sheet apply to the maximum air flow of the relevant fan. In practice, this rarely occurs, because at this point the static air pressure is almost zero.

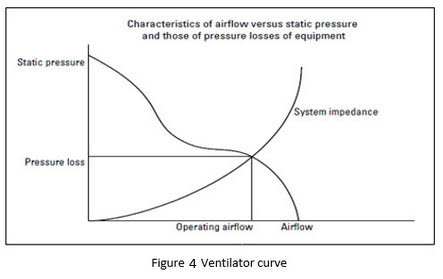

As shown in the graph below, this one has a somewhat flatter part in the middle (see figure 4). This is the stall area of a fan and we want to avoid this because the fan can exhibit unstable behavior here. We also want to avoid the part to the left of the stall area, because this is where the stall is even worse and power consumption and noise production are highest.

In the graph we can see that the point of the intersection of both curves is just slightly to the right of the flat part of the fan curve; we call this the ideal operating point of a fan and is actually the ideal point in terms of thrust and air flow. With the calculation we made earlier, it must therefore always be checked whether the nominal airflow reaches this point.

We can therefore say that we are already well on the way with the calculation.

Yes, by measuring the air resistance and air flow. But this is easier said than done. There are a number of instruments that can be used, such as an anemometer (wind speed meter) and air pressure gauges. But where exactly are you going to place these? So the result will not be very accurate and reliable. The best results are obtained by testing with a so-called double chamber. These are large and expensive devices that are normally only found in larger laboratories; an expensive affair.

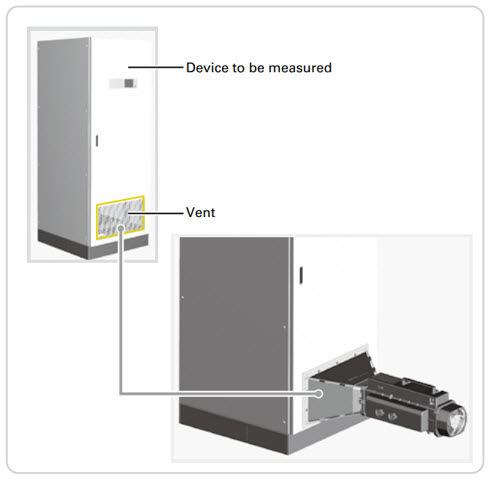

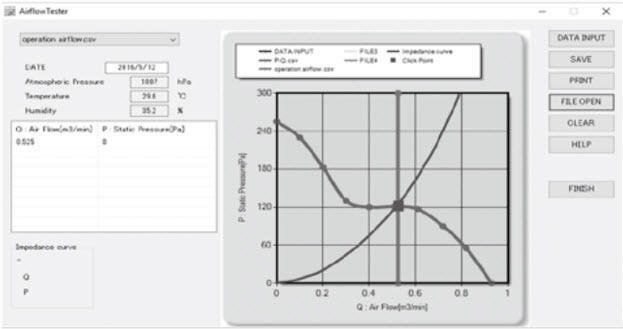

Sanyo Denki has come up with a good alternative for this, the air flow tester. This is a portable device with which the static air pressure and air flow of the device to be cooled can be measured. So you immediately have the properties of your device to be cooled.

With this, the ideal point of use can then be determined and a fan can be selected. In this way a very reliable result is obtained and no safety margin needs to be applied.

Because the airflow meter is portable and you can make your own template for your device, it can be used for almost anything. The Air-Flow-Tester is available to rent and an advisor can also assist with the usage. In this way, the best fan for your application can be selected at low cost, with an optimal combination of air flow, static pressure, power consumption and noise.

Video