October 30, 2024

In our daily lives we are surrounded by a huge number of displays and a growing quantity of devices use a display as the primary Human Machine Interface (HMI). In this TOP TECH TALK, we discuss some of the latest technologies available in consumer devices and consider their suitability for incorporation into industrial products.Voice commands, and AI are revolutionizing how we interact with technology.

The traditional methods of interaction - keyboards, touchscreens, and physical buttons - are being complemented, and in some cases replaced, by more intuitive, natural ways of communication. As we step into this new era, the integration of voice command systems with advanced AI is poised to redefine the user experience across industries.

Although considered a mature technology, TN (Twisted Nematic) TFT technology was the dominant technology for years and is still worth a mention as it ‘sets the scene’ for all the other display technologies.

|

|

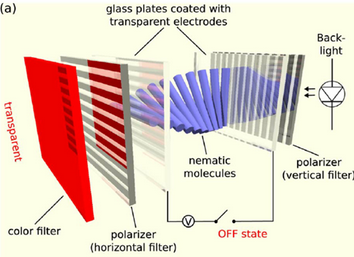

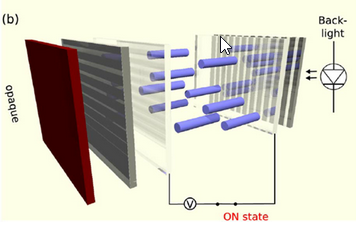

Figure 1, TN How does it work?

As seen in Figure 1 (Source), TN turns light on and off by controlling a twisted helix of liquid crystals. In common with all full color display technologies, each pixel has red, green and blue (RGB) sub-pixel constituents, in this case, in the form of color filters that are individually turned on and off.

In Figure 1a each sub-pixel cell is normally on when no voltage is applied. This is due to the helix arrangement of the crystals bending the light through 90 degrees. The sub-pixel cell, in this case a red one, becomes dark (b) when a voltage is applied to the transparent electrodes due to the crystals aligning with the voltage and preventing the light from passing through from the backlight.

TFT, also referred to as Active Matrix, uses a Thin Film of Transistors inside the display structure to directly control the individual pixels. TN TFT technology is relatively easy to manufacture and is low cost. The display response times are fast and there are no burn-effects or image retention. However, viewing angles are poor which is usually the biggest issue today for industrial use. Added to this, the color accuracy is generally poor due to most designs having 6-bit resolution per sub-pixel color, which gives just 64 different shades of each color - red, green and blue.

In Plane Switching displays offers a big upgrade over traditional TN, because this technology offers the benefit of very wide viewing angles and much higher color accuracy and resolution. The display response times however are slightly longer than for TN.

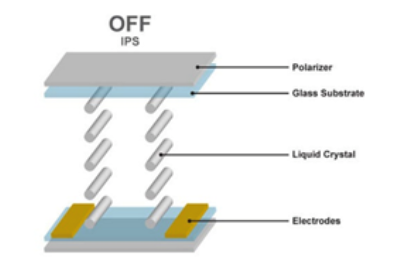

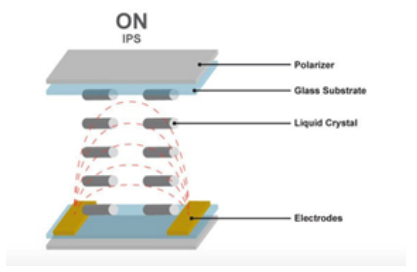

In terms of structure, the crystals are arranged to switch polarity within the same orientation plane as the display surface, hence the name ‘in-plane switching’.

Contrary to the action of TN; the default state of the crystals blocks the light from the backlight. When an electric current is applied, the crystals re-align with the field and light passes through.

|

|

Figure 2, The Structure of IPS LCD

Although IPS is not as power-efficient as TN, new backlight technologies make these displays extremely bright and clear. Importantly, IPS does not suffer any burn-in effects, and combined with its price performance ratio, excellent color accuracy and wide viewing angles it is close to ideal for many industrial use cases.

TOP-electronics distributes the range of IPS TFT displays. They have panel sizes from 1.3-inches to 15.6-inches, and up to 2000nits in terms of brightness (currently). These displays feature exceptional 10 000 : 1 contrast ratios, and are available at a very competitive pricing level.

Not to be confused with Micro LED, Mini LED is actually a backlighting technology which is normally used on large IPS TFT television panels. It uses an array of very small LEDs to provide (currently) several thousand local-area dimming zones on the backlight, which are controlled in concert with the display pixels.

This technique permits the turning off of the backlighting in the black zones, which helps to produce a much blacker effect thereby greatly increasing the contrast ratio.

The LEDs used for this application can be as small as 0.2 mm across, and for this reason the technology is already starting to migrate to some smaller panels where it can be used to good effect. For example, the 2021 iPad Pro uses 10 000 LEDs with 2 500 dimming zones on its 12.9-inch IPS screen.

Over time, as the LEDs become smaller and the driver silicon more readily available, we predict that this technology will also become applicable to Industrial panels as well, because it’s based on IPS and traditional LEDs, there are no burn effects associated.

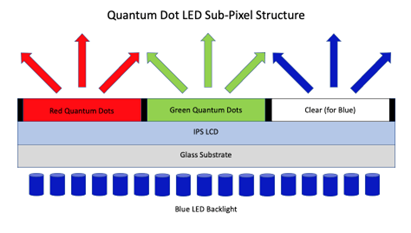

Figure 3, Quantum Dot Nanocrystal Displays

With the advent of Ultra HD content there is an industry requirement for a display technology with a more accurate color range than existing traditional color filters. Quantum dots are also called nanocrystals and are actually the creation of Bell Labs and date back to the 1980’s. This technology was revived to create a new generation of color filters. Quantum dots are produced with semiconductor technology and use nanoparticle crystals in their construction. As shown in Figure 3, they work at the RGB sub-pixel level by transforming blue (or ultra violet) light sources into red or green light. The blue constituent is made up by having a transparent sub-pixel Quantum dot cell. The backlight used is therefore blue and passes through the IPS LCD to turn off and on each pixel and RGB subpixel.

Since the resulting color is actually a function of the crystal structure, the result is a significantly increased color range providing more natural color rendition and deeper saturation. This can be used in conjunction with local area dimming to provide deeper contrast ratios. There are no burn effects associated with Quantum Dot technology, and because the blue backlight energy is transformed by the quantum dots rather than filtered this produces an increase in image brightness.

We anticipate that as volumes increase and costs reduce that Quantum Dot Technology could well become accepted in the industrial space as a way to get even deeper color resolution in conjunction with IPS technology.

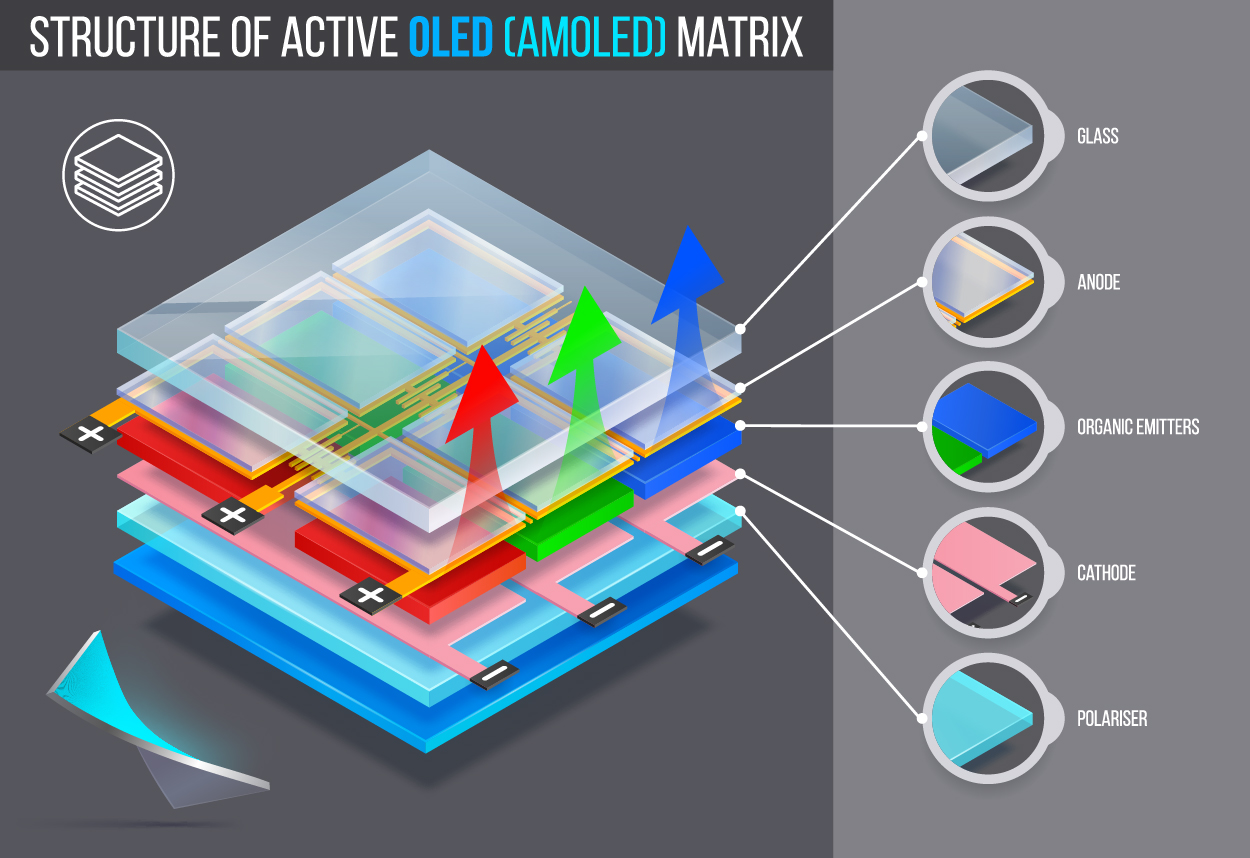

OLED is an abbreviation for Organic Light Emitting Diode. With this technology each pixel and RGB Sub pixel is made up of a tiny light emitting diode that emits light according to the voltage applied. Because OLED is based on an emissive technology, when no voltage is applied to the LED’s, the pixel is truly black since no light is being generated. This means there is an extremely good contrast ratio and both color accuracy and viewing angles are excellent.

OLED technology comes in two flavors with AMOLED and PMOLED, meaning active or passive matrix, which describes whether the drive transistors are placed in the structure of display or externally respectively.

Figure 4, The Structure of OLED

One of the challenges with OLED is that it can suffer from problems of burn-in, which means that if the same image is displayed for a long time the pixels that are lit up could become ‘burned’ and no longer produce as much light as the others, leaving traces on the screen which are visible when the screen images changes. There have been a lot of developments over the years to mitigate these effects and these do now work to great effect, but unfortunately burn-in is still an underlying concern for this technology, as is the higher production cost.

Recent innovations include the creation of WRGB sub pixels on some OLED panels with an additional White sub-pixel, which is used with the RGB sub-pixels to augment the brightness, However, improvements in traditional backlighting technology means that IPS TFT has the edge in terms of brightness.

Panel and tooling costs for AMOLED are comparatively high compared to TFT, and despite the many advantages, AMOLED and PMOLED displays are not so widely adopted in industrial use cases, primarily because of burn-in and lifetime concerns.

Electronic paper, also electronic ink, e-ink or electrophoretic display, are display devices that mimic the appearance of traditional ink on paper, offering high visibility in direct sunlight and ultra-low power consumption. Unlike conventional flat panel displays that emit light, an electronic paper display reflects ambient light like paper. E-paper displays are commonly found in e-readers and e-ink price tags.

STN stands for “Super Twisted Nematic” and is a type of liquid crystal display technology. It’s a mature technology that has been around since the early 1980s and tends to be used in passive matrix monochrome graphic and alphanumeric displays. This technology offers a number of benefits, including fast response times, high transmittance, low power consumption and good contrast. However, there are some limitations, such as a fairly narrow viewing angle and very limited colour capabilities. Despite these limitations, STN displays remain an important technology in the display industry, particularly in applications where low current consumption and low cost are key factors.

When choosing an STN display, it’s important to know if you require a Reflective, Transmissive or Transflective polariser.

A Reflective LCD polariser is nothing more than a mirror that is applied to the bottom layer of glass. It reflects 100% of the ambient light entering through the top layer of glass back towards the user. The brighter the ambient light, the sharper the contrast and the easier it is to read. Although if there is little or no ambient light then the display will be difficult to read.

A Transmissive LCD polariser, unlike the reflective polariser, only allows light from a backlight to pass thought the bottom and top layer of glass towards the viewer. The backlight must always be on for the display to be readable. This technology is generally used with negative mode displays (light characters/graphics on a dark background)

The Transflective LCD polariser is a hybrid of both Reflective and Transmissive options. It reflects some of the ambient light passing through the front of the glass and at the same time allows some of the light from the backlight to pass through to the front layer of glass. It’s the best of both worlds and is the most popular of the three LCD polariser technologies, as it allows the display to be read with or without the backlight (depending on the ambient conditions). Transflective displays are mostly used in applications such as e-readers, smartwatches, and outdoor devices.

Touchscreen technology has come a long way since its early days, and there are now several different types available. Each type of touchscreen has it’s own benefits and drawbacks, depending on factors such as accuracy, cost and durability. In reality, the industrial market sector tends to be dominated by resistive touchscreen and capacitive touchscreen technologies, there are however other technologies available.

Resistive Touchscreens

Resistive Touchscreens are a popular and cost-effective type of touchscreen technology. They consist of two thin layers of conductive material, separated by a small gap, when pressure is applied to the top layer, it flexes and makes contact with the bottom layer, which completes and electrical circuit and registers the touch. This technology is known for its durability and resistance to dust, moisture and temperature changes.

They can be used with any object, including fingers and styluses, making them versatile for various applications. On the downside, resistive touchscreens generally have low touch resolution, which means they may not be as sensitive or precise as other touchscreen technologies. Typically, they also don’t can’t support multi-touch gestures, so can’t be used if the customer requires “pinch and zoom” type features.

Resistive touchscreens can also make the display look slightly dimmer, or hazy/fuzzy, due the the additional layers

Capacitive Touchscreens

Capacitive Touchscreens are now arguably the dominant touchscreen technology in the market, mainly due to the popularity of mobile phones and tablets. It is a more advanced type of touchscreen technology that relies on changes in an electrical field, rather than pressure (like resistive touchscreens). They are generally made up of a glass panel coated with a conductive material, such as indium tin oxide (ITO), that creates a uniform electrostatic field.

When a conductive object, such as a finger touches the screen, it disrupts the field and registers the touch location. This technology is also known for its high touch resolution, which allows for precise input and support of multi-touch. One drawback of this technology is that it requires a conductive material to register a touch, so they may not work with gloves or some styluses. This technology can also be sensitive to moisture and dirt, which can interfere with the electrical field, and start to report “false” touches. Capacitive touchscreens also tend to be more expensive than their resistive counterparts.

Whilst most applications, that require a touchscreen, will use either a resistive or capacitive technologies, it should be noted that other technologies, like Infrared Touchscreens, Surface Acoustic Wave Touchscreens and Optical Imaging Touchscreens are available.

Infrared Touchscreen (IR)

This technology creates an invisible grid of infrared light beams across the surface of the screen. When a user touches the screen, they interrupt these beams at the point of contact, allowing the system to precisely detect the touch location. IR touchscreens are known for their durability and high accuracy, making them suitable for rugged environments or larger interactive displays.

Surface Acoustic Wave Touchscreen (SAW)

SAW technology utilizes ultrasonic waves transmitted across the surface of the glass. When touched, the contact point disrupts these waves, enabling the system to detect the exact location of the interaction. Surface Acoustic Wave touchscreens offer excellent clarity and responsiveness, often used in high-precision applications such as kiosks and public terminals.

Optical Imaging Touchscreen

Optical touchscreens rely on infrared sensors placed along the edges of the screen, which monitor movements across the surface. As an object, such as a finger or stylus, touches or nears the screen, it alters the infrared light pattern, allowing the system to map the exact position. This technology is ideal for large displays and offers multi-touch capability and high touch sensitivity.

While touchscreens are a popular choice for operating displays, other technologies offer unique advantages depending on the application. Rotary encoders and push buttons provide alternative methods of interacting with and controlling displays, especially in environments where precision, durability, or specialized input methods are required.

For instance, rotary encoders from SameSky allow for highly accurate rotational input, making them ideal for applications in industrial automation, robotics, or machinery, where fine control is necessary. These devices are essential for precise measurement of the angular position and motion of mechanical systems.

These high-performance rotary encoders are designed to deliver accurate feedback and control in demanding environments. Whether for robotics, manufacturing, or process control, these encoders ensure seamless integration with Human Machine Interfaces (HMIs) for real-time position sensing and enhanced operational efficiency. The rotary encoders are available in various configurations, including incremental and absolute models, to meet diverse application needs.

Meanwhile, push buttons from Summit Electronics provide a reliable and tactile method for interacting with devices. These push buttons are designed to offer precise control in environments that demand quick, straightforward input. Summit Electronics’ push buttons are well-suited for a wide range of industrial applications, where durability and responsiveness are critical. They feature rugged construction for long-lasting performance, making them ideal for harsh industrial conditions.

Whether used in control panels, machinery, or other industrial equipment, Summit’s push buttons integrate seamlessly into modern HMI systems, offering robust and dependable input for system control.

These technologies—rotary encoders and push buttons—expand the possibilities for display operation, providing flexibility and enhanced control across a variety of industrial applications.

For a lot of projects now, the TOP-electronics team see the demand for Custom cover glass / cover lenses growing. When designing a cover lens for an LCD or TFT Display, there are several factors to consider to ensure optimal performance and durability. What needs to be considered is the selection of material, thickness, mounting, costs and more.

Material Selection

Choosing the right material for your cover lens is crucial for achieving optimal performance. At TOP-electronics, we can guide you in selecting materials that offer transparency, scratch resistance, and low reflectance to minimize glare. Common choices include polycarbonate and glass, though other specialized options are available depending on your requirements.

Touch Facility

Assistance is given in deciding, if required, on what touch requirements are needed. Often, only a part of the cover glass is required to be used as a touchscreen.

Thickness

The thickness of the cover lens is a key factor in both protection and visual clarity. We can also assist in ensuring that your lens is thick enough to safeguard the LCD while minimizing parallax effects, which can impact readability.

Finish

Enhance the visual appeal of your cover lens with custom finishes. We offer silk/screen printing to achieve tinted, colored, or textured effects - including the option to display your company logo.

Surface treatment

To improve the user experience, we can apply various coatings and surface treatments that reduce glare, reflections, and fingerprints. These enhancements contribute to better visibility and a cleaner appearance in various lighting conditions.

Mounting

Proper mounting is essential for a secure and durable assembly. Our engineers work closely with your mechanical design team to ensure the cover lens integrates seamlessly with the display and the overall product housing, providing a robust final solution.

Environmental Considerations

Understanding the environmental conditions in which your product will operate is vital for long-term performance. Our experienced engineers consider factors like sunlight exposure, moisture, and extreme temperatures to ensure your cover lens can withstand harsh conditions.

Cost Optimization

Balancing performance and budget is always a priority. We focus on providing a cost-effective solution that meets the functional requirements of your application without compromising quality.

Voice command technology has emerged as a significant trend in HMI, offering a hands-free, efficient way to control devices. This technology is particularly transformative in environments where manual operation is challenging, such as in automotive, industrial automation, and smart home systems. By using natural language processing (NLP), voice command systems can understand and execute complex instructions, making them an invaluable tool in modern HMI.

ARK-X, a leading supplier in this space, provides state-of-the-art voice command solutions designed to seamlessly integrate with various devices and applications. Their solutions are engineered to offer high accuracy in noisy environments, ensuring reliable performance even in the most demanding conditions.

The integration of AI with voice command systems takes HMI to the next level. AI-driven voice recognition systems are not only capable of understanding spoken commands but can also adapt to user preferences over time. This personalized interaction enhances user satisfaction and drives more intuitive and efficient operations.

Moreover, AI enables voice command systems to interpret contextual information, allowing machines to make informed decisions autonomously. For example, in an industrial setting, a machine equipped with AI and voice recognition can adjust its operations based on verbal feedback from the operator, improving both safety and productivity.

While voice commands and AI are transforming HMI, display technology remains a crucial component of the interface. Modern displays serve as the visual bridge between the user and the machine, providing real-time feedback and critical information.

The future of display technology is headed towards more interactive and adaptive screens, capable of responding to voice commands and AI-driven insights. For instance, a machine operator could use voice commands to bring up specific data on a screen, with the display adjusting dynamically based on the context of the operation. This level of integration between voice commands, AI, and display technology creates a more fluid and responsive HMI.

IPS looks likely to remain a core technology for industrial panels certainly for the immediate future. There are many reasons for this: The excellent price versus performance ratio plus wide viewing angles and large contrast ratios combined with the very good color rendition and lack of burn-in concerns. Added to all of this, developments in backlighting technology have steadily made the panels brighter and brighter, which has further expanded market appeal as well opening up new use cases.

Technologies such as mini-LED backlighting and quantum dots are gaining momentum in the consumer segment to further push the envelope of what IPS can do. As these technologies becomes more accepted, available and widespread, we predict they could start to find application in the industrial market segment further contributing to the dominance of IPS as the premier display technology for industrial use cases for many years going forward.

The fusion of voice command technology with AI and advanced display systems represents a significant leap forward in HMI. As these technologies continue to evolve, we can expect to see more intuitive, efficient, and user-friendly interfaces across various sectors. Our partners are at the forefront of this transformation, providing innovative voice command solutions that pave the way for the next generation of human-machine interactions. As the industry continues to innovate, the synergy between voice, AI, and display technologies will play an important role in shaping the future of HMI.

For more information on TOP's technologies, reach out to [email protected], or give us a call at +31 (0)180 - 580 492

Image Source: Elze, Tobias & Tanner, Thomas. (2012).

Temporal Properties of Liquid Crystal Displays: Implications for Vision Science Experiments.

PloS one. 7. e44048. 10.1371/journal.pone.0044048.