October 8, 2025

Goermicro Vzense industrial-grade 3D ToF camera provides high-precision 3D vision solutions based on advanced optical design and depth perception algorithms. It features a ranging accuracy of ±1mm, a dynamic range of 5 meters, and a point cloud output of 640*480@30fps, and has passed IP67 protection and wide temperature range certification.

It supports industrial protocol integration and SDK secondary development, and is widely used in precision inspection, AGV navigation, logistics sorting and intelligent manufacturing, inspection, people counting, pallet handling, and more promoting the upgrade of industrial automation with stable and reliable performance to meet the intelligent needs of Industry 4.0.

Key capabilities & Technical highlights

These capabilities position the Vzense platforms as reliable building blocks for automation systems that demand high accuracy and stability under real‑world conditions.

AGV / AMR & Mobile Robots

Conventional RGB cameras lack direct distance measurement, which limits their use in obstacle avoidance and spatial awareness. ToF cameras fill this gap by giving direct depth maps, enabling robots to perceive their surroundings in real time. Integrating Vzense ToF sensors allows AGVs/AMRs to:

These benefits help make mobile robots safer and more efficient in industrial settings.

Enhancing Autonomous Navigation

To operate autonomously in unknown or changing environments, AGVs must sense and interpret their surroundings with speed and reliability. The Vzense 3D ToF camera delivers:

With these features, Vzense enables safer, more efficient autonomous navigation.

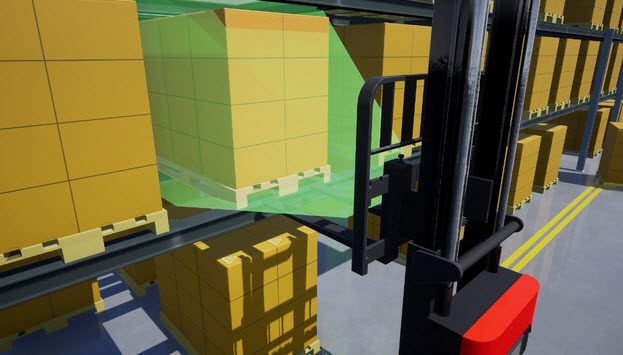

Pallet Detection & Autonomous Forklift Operation

Vzense designs some models as RGBD hybrids, meaning they combine an RGB (color) sensor and a depth module in one unit. In autonomous forklift environments:

This dual-modality approach improves robustness, particularly in mixed-material or low-contrast scenarios.

Smart Material Handling & Industrial Automation

Vzense’s 3D ToF camera technology is purpose-built to support a wide range of automated handling and industrial automation applications, from palletizing and depalletizing to load management and process monitoring.

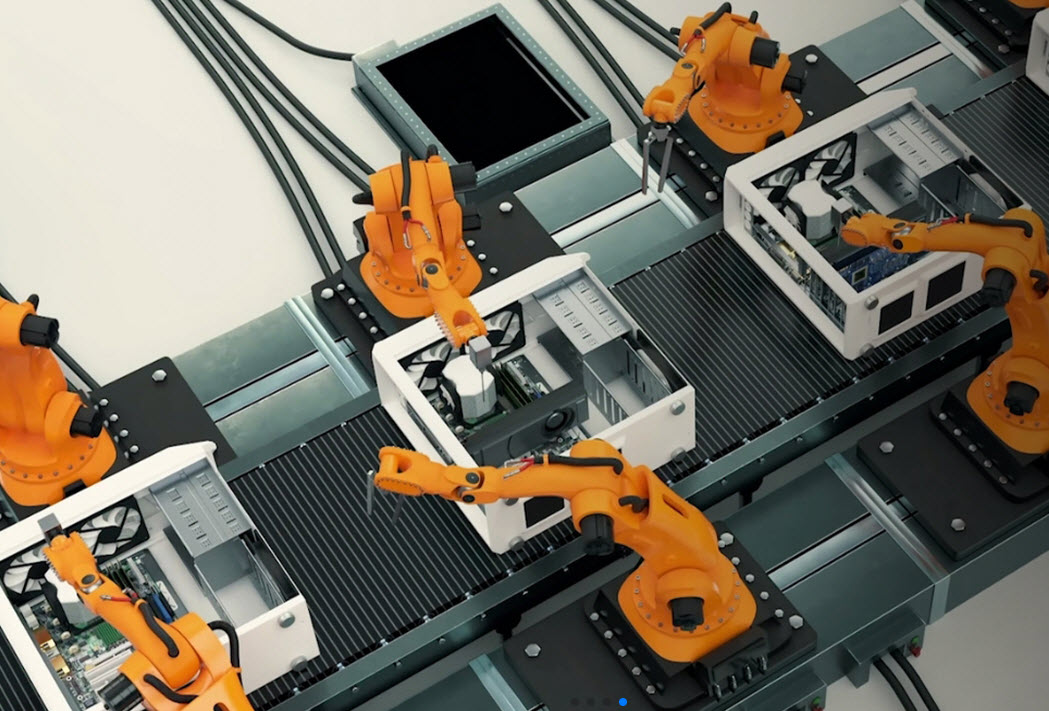

Precision Palletizing and Depalletizing

In robotic palletizing and depalletizing, Vzense depth sensors guide robotic arms with high precision, enabling accurate picking, stacking, and placement — even with irregularly shaped or variably stacked items. These systems improve speed and safety in warehouse and factory environments, reducing reliance on manual labor.

Advanced load handling with iToF

Handling diverse loads requires the ability to recognize complex geometries and surfaces without physical contact. Vzense’s iToF (indirect Time-of-Flight) cameras offer:

This makes Vzense ideal for unmanned forklifts, pick-and-place systems, and smart conveyors, supporting “non-contact identification” and ensuring traceability and safe handling across a variety of materials.

Broader automation integration

Beyond material handling, ToF sensors play a vital role in general factory and process automation. Key applications include:

The compact, ruggedized design of Vzense cameras allows for flexible deployment in logistics, assembly, food processing, and smart manufacturing environments.

People counting with privacy protection

Vzense offers AI-integrated 3D ToF camera solutions for intelligent people counting in public transportation, retail, and commercial spaces. Key features include:

These systems are ideal for managing occupancy, optimizing space usage, and improving resource allocation — all while respecting privacy.

The shift toward smart factories and autonomous systems demands reliable 3D perception that can operate under variable lighting, dust, vibrations, and space constraints. Vzense ToF cameras offer:

Together, these features accelerate the rollout of intelligent automation and elevate system-level reliability in Industry 4.0 infrastructures.

The DS series ToF and RGB cameras developed with SONY's latest DepthSense chip, the IMX570. They utilize 940nm infrared light, making them suitable for both indoor and outdoor scenes.

The ToF resolution is 640x480, with a frame rate of up to 15 frames per second. The depth camera has a field of view (FOV) of 67° horizontally and 50° vertically.

The RGB camera resolution is 1600x1200, with a global shutter and an FOV of 70° horizontally and 50° vertically. The detection range is from 0.15m to 5m, with an absolute accuracy better than 1% and a relative accuracy of about 0.5%.

The DS series includes two models:

DS86 and DS87. While they are essentially the same in most respects, there are some key distinctions:

IP Rating: The DS86 has an IP42 rating, while the DS87 boasts an IP67 rating due to its physical connection method of M12+M8 aviation plugs.

Power Supply Method: Only the DS87 supports Power over Ethernet (PoE).

Size: Consequently, the DS86 is slightly smaller than the DS87.

The table below highlights the main differences between them.

|

Product |

Model |

ToF Sensor |

ToF Resolution |

ToF Frame Rate |

ToF FoV |

PoE+ |

RGB |

Shutter |

RGB Resolution |

Interface |

IP Rating |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Sony IMX570 CMOS |

640*480 |

Max. 15fps |

67°(H)*50°(V) |

No |

Yes |

Global |

1600 * 1200 |

RJ45 + M8 Aviation Plugs |

IP42 |

||

|

Sony IMX570 CMOS |

640*480 |

Max. 15fps |

67°(H)*50°(V) |

Yes |

Yes |

Global |

1600 * 1200 |

M12 + M8 Aviation Plugs |

IP67 |